Do batch processing, loading trays, handling trolleys and opening the oven door on your combi oven slow down your kitchen? Learn more about how TWIN-COOK conveyor oven works, its benefits, and how it can save time in your production kitchen operations.

Say goodbye to batch cooking. Experience the batch processing alternative by changing to a continuous cooking process. No more waiting for batches to finish!

Imagine a cooking process with no doors to open, no trays and no trolleys to handle! Twin-COOK contact grill eliminates batch-cookingand save valuable time.

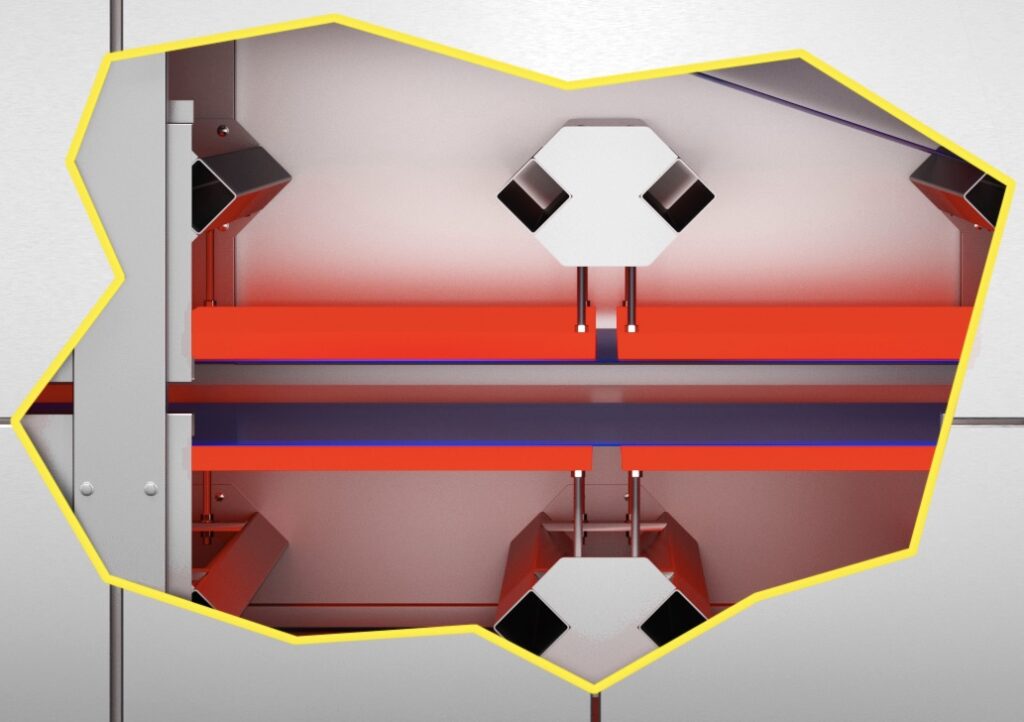

The SPC system is a double-contact oven that can cook a wide variety of foods. This system ensures continuous production by eliminating manual labor and the need for thorough cleaning of the machine between product changes.

Whatever your cooking goals, the SPC can pre-cook or fully cook your products.

Choose your own cooking settings: the distance between the cooking plates, the heating temperatures, and the cooking time are all independent of your control.

?

?

Time is of the essence in production kitchens. Go for a time-saving cooking solution. TWIN-COOK continuous contact grill is designed to cut your cooking time in half compared to traditional ovens. This means you can cook faster and keep up with high-capacity scenarios. Continuous cooking is more efficient.

TWIN-COOK conveyor oven is the batch processing alternative for commercial kitchens. The continuous cooking process eliminates the use of racks, trolleys, opening and closing oven doors. This high capacity conveyor oven reduces working time and labor cost. TWIN-COOK use direct contact heat from two sides simultaneously. Direct contact shortens the cooking time and increase the productivity. Cook, grill, fry or roast burgers, patties, chicken, bacon, pork chops, steaks, breaded schnitzel, fish portions more effectively!

| Twin-COOK Pilot | Twin-COOK 4.1 | Twin-COOK 4.2 | Twin-COOK 6.2 | |

|---|---|---|---|---|

| Burgers Ø130xT12 mm, 165 g., 1 min, cT 72°C |

65 kg/h | 130 kg/h | 260 kg/h | 390 kg/h |

| Bacon 38% yield, 190x38x2 mm, 16 g., 1 min |

16 kg/h | 32 kg/h | 64 kg/h | 95 kg/h |

| Chicken fillets 90x160x25 mm, 190 g., 4 min 24 sec, cT72°C |

27 kg/h | 55 kg/h | 110 kg/h | 165 kg/h |

| Boneless chicken thighs 80x110x22 mm, 88 g., 3 min 48 sec |

20 kg/h | 40 kg/h | 80 kg/h | 120 kg/h |

| Pieces of beef 110x170x19 mm, 380 g., 3 min 24 sec |

50 kg/h | 100 kg/h | 200 kg/h | 300 kg/h |